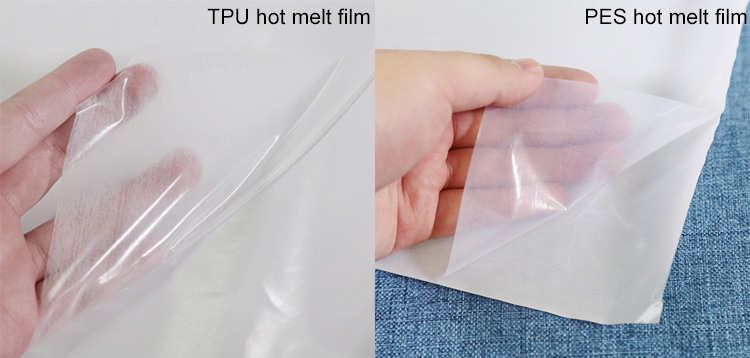

Comparison of TPU hot melt film and PES hot melt film

Different in materials

TPU is short name for thermoplastic polyurethane elastomer rubber, is a kind of polymer material between rubber and plastic, heating can be plasticized, wear-resistant, good water resistance. Acording to the melting point, TPU hot melt film can be divided into high melting point type and low melting point type, and the higher the melting point, the greater the elasticity, low melting point is not elastic.

PES hot melt film is composed of polyethylene glycol succinate, a biodegradable chemical synthetic polyester. Its melting point is 125-130℃ and its operating temperature is 130-150℃. Its main characteristics are water resistance, inelasticity and excellent waterproof performance, which can be used in the water treatment industry.

PES hot melt film costs less

Different fields of application

TPU hot melt film can be said to be the most popular and widely used hot melt film of all materials, can be used to bond textiles, elastic cloth, leather, sponge and TPU film, suitable for clothing, home building materials, shoes, daily necessities and so on.

PES hot melt adhesive film can also be used for PET film, rubber, metal material bonding, clothing and industry has been the application of PES hot melt film is very common industry.