What’s tricot interfacing and how about the application?

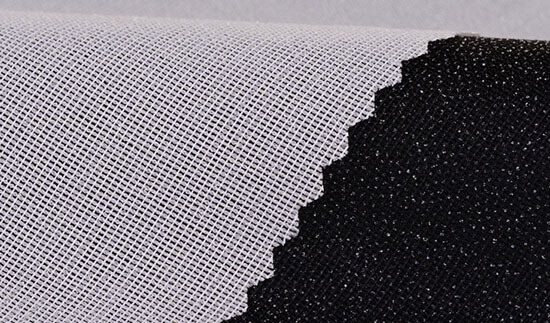

tricot interfacing (warp knitted interlining)

The warp knitted interlining is a kind of fusible interlining, and some people also say it two way stretch interfacing or tricot interfacing. It is made of warp knitted fabric as basic fabric and coated with glue powder. In general, warp yarns are crocheted into each other in weft direction. This kind of structure makes warp knitted fabric soft and elastic.

The characteristics and purposes of warp knitted interlining are as follows:

The organization of the interweave of the warp yarn is the method of filling in the weft insertion, which is low cost and high efficiency.

The tricot interfacing needn’t go through resin finishing so it doesn’t contain formaldehyde. Because the technical process is short, there is little pollution during processing, it can be called environmental protection fusible interfacing.

The base cloth of warp knitted interfacing is polyester filament yarn or viscose yarn. The warp direction is smooth and the weft direction has the good elasticity, better flexibility and adapt to elastic fabrics.

The excellent characteristics of warp knitted fabrics make it possible to meet the needs of different textures and styles from light to heavy weight. Fully adapted to the various kinds of fabrics and clothing requirements for the adhesive lining.